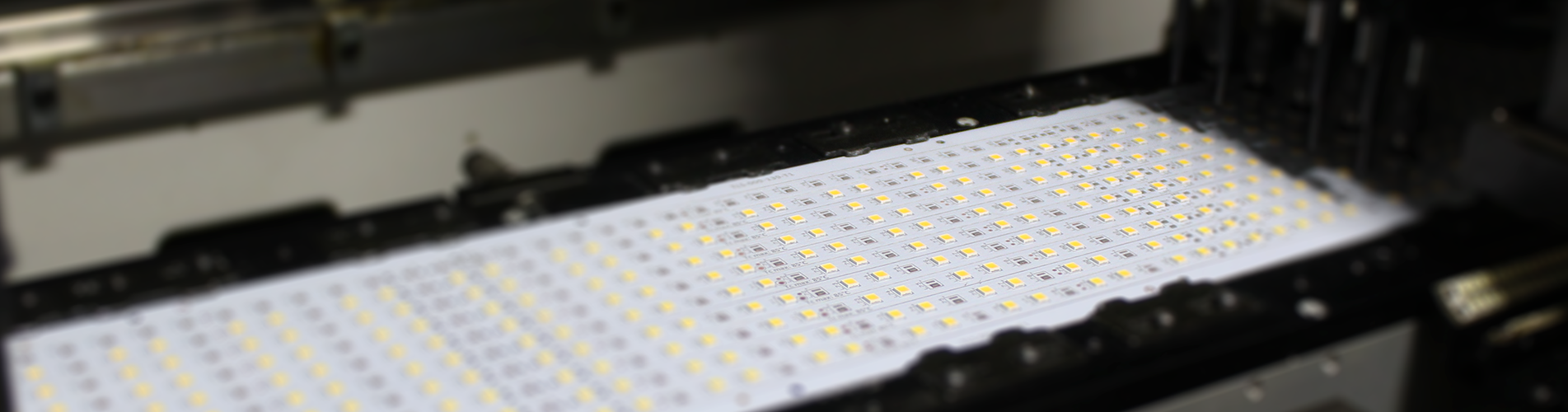

LED AND ELECTRONIC ASSEMBLY LINE

With our 3 fully automatic SMT Composition Lines, we are able to string 150,000 Components per hour on average. It is aimed to realize an error-free production by creating heat profile curves specifically for each module.

Our company, which has been developing and growing for many years. It supports the lighting industry with our SMT line that meets all standards according to ISO 9001 rules. Our track is operating with our SMT machines SM481, SM471, SLM120. In particular, the components that come to production are compared one by one and the ones that are found suitable are given to production.

SM 481 Plus SMD Line

Fast, Precise, Flexible, Functional SMT Line

- Optimal SMT Capacity 40,000 comp/hour

- IPC Speed: 32.000 comp/hour

Component SMT Capability

- 01005,0201,0402,0603,0805 inch and larger chips and SOP,SOT,PLCC…Type components,

- Micro processor with 0.3 mm distance, BGA, Micro BGA, QFN, CSP Smd SMD connectors,

- Components up to 42 x 42 mm have a placement capability.

- It has SMD stringing capability up to 600mm PCB length..

SMT Precision

- For QFP and similar ICs ± 30 ㎛ ±3σ

- ± 40 ㎛ ±3σ for chips and similar components

- With Fly-Vision Camera Technology, 16 x 16 mm in size and H: 12 mm in height, including all IC, BGA, Micro BGA, QFP, can make very fast and optimal typesetting without using a fixed camera.

SM 471 Plus SMD Line

Fast, Precise, Flexible, Functional SMT Line

- Optimal SMT Capacity 78.000 comp/hour

- IPC Speed: 62.000 comp/hour

Component SMT Capability

- 01005,0201,0402,0603,0805 inch and larger chips and SOP,SOT,PLCC…Type components,

- Micro processor with 0.5 mm distance, BGA, Micro BGA, QFN, CSP Smd SMD connectors,

- Components up to 14 x 14 mm have a placement capability.

- It has SMD stringing capability up to 600mm PCB length..

SMT Precision

- For QFP and similar ICs ± 50 ㎛ ±3σ

- ± 40 ㎛ ±3σ for chips and similar components

- With Fly-Vision Camera Technology, 14 x 14 mm in size and H: 12 mm in height, including all IC, BGA, Micro BGA, QFP, can make very fast and optimal typesetting without using a fixed camera.

SLM 120 Serisi Smd Dizgi Makinesi

SAKI - BF-Frontier II 2D Machine

Saki has a 2D AOI inspection system for companies of all sizes and for every need. Whether it's offline, online, single lane, dual lane, XL, benchtop, a system capable of simultaneously running two-sided boards or any other, Saki has the answer of all of this options.

Saki 2D AOI systems employ a telecentric lens optics system to capture the sharpest images. The system corrects the brightness of the entire sample and compensates for misalignment in real time while scanning; thus, examination results become accurate, reliable and repeatable over time. Various algorithms and solutions to meet a wide range of industry inspection requirements lighting types are available. Various data processing features have been added to flexibly deal with line requirements, such as changing settings with barcode reading and outputting data to the customer's data server.

Hygienic Production Area

The ventilation system, humidity and dust values required to provide a workable environment in the production area, ESD (antistatic) epoxy floor and an infrastructure system to take the electric charge in the environment is divided.

Input and Output Quality Control

All components required for production are prepared and sent to production. In the input quality control, the components that come to order and production are compared one by one. Those deemed appropriate are given to production.

Output quality control is the final control of the main products produced within the technical specifications.

QR Barcode Tracking

In order to follow the production, QR Barcodes are prepared and pasted on each module.

In our QR Barcode tracking system, it is possible to access all information such as which Lot Numbered products, which SMT machine used, who lined up, who tested it and who packaged it…etc.

Packing and Antistatic Protective

All products are packed with anti-static packaging products in a way that will not harm each other and become ready for shipment.